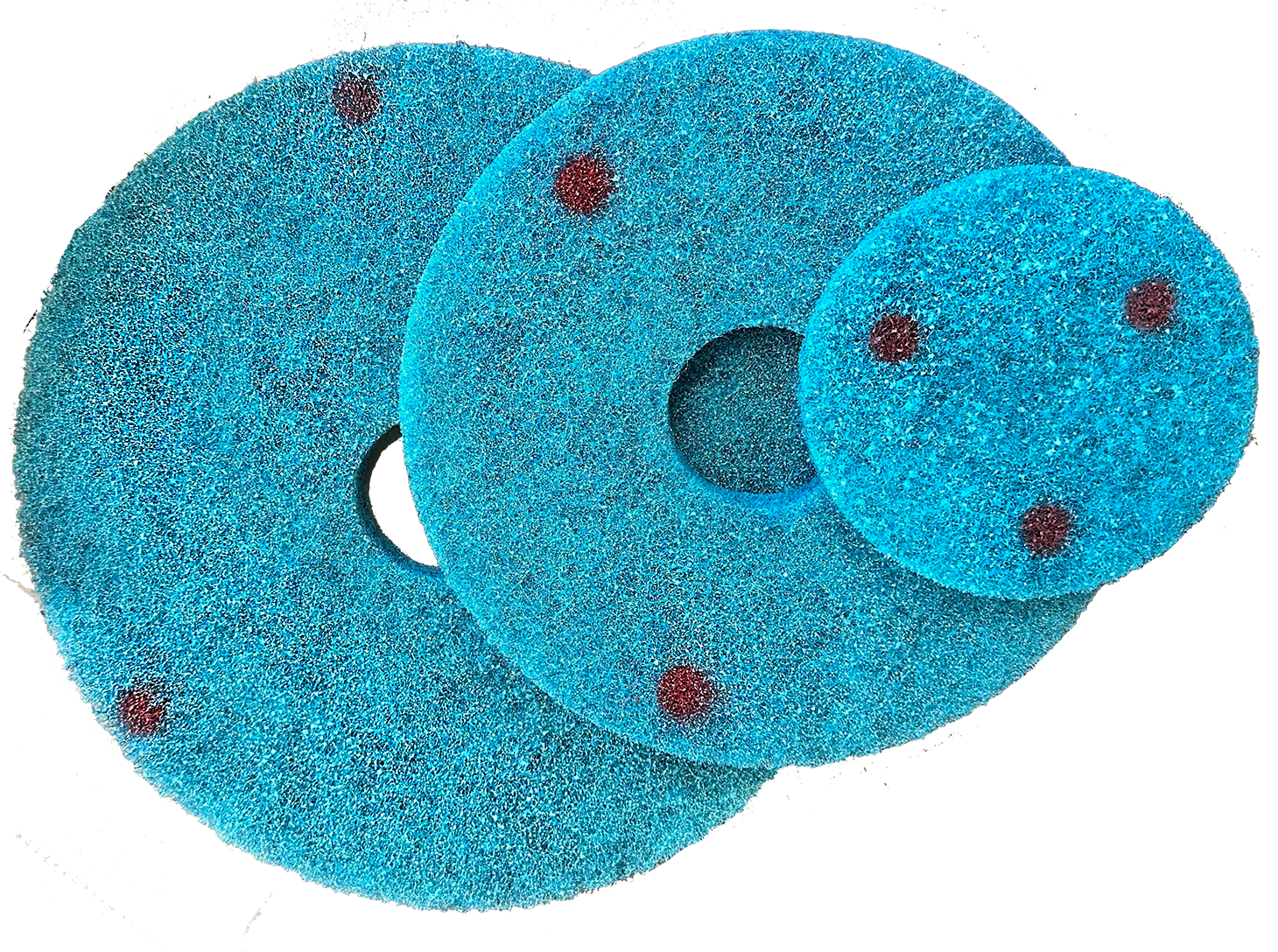

Enhance Stone Restoration with PLP Diamond Impregnated Pads (DIPs): Wet & Dry Applications for Marble, Concrete, and MoreMaximizing Shine and Efficiency with PLP Diamond Impregnated Pads (DIPs) for Stone Restoration Diamond Impregnated Pads (DIPs) have become an essential tool in the stone restoration industry for maintaining and enhancing the beauty of surfaces like marble, limestone, terrazzo, and concrete. These pads utilize microscopic diamonds, providing an efficient, cost-effective solution to professional contractors. Versatile Use of DIPs: Wet or DryThe versatility of PLP Diamond Impregnated Pads lies in their ability to be used wet or dry, at both slow and high speeds. For honing marble or similar surfaces, the 100-grit and 200-grit pads are ideal. At slow speeds (around 175 RPM) and used wet, these pads deliver optimal cutting power, making them perfect for honing countertops and floors. On the other hand, for contractors aiming to achieve a high-gloss finish, the DIPs can be used dry and at high speeds (over 1500 RPM), often with burnishers. This dry application tends to produce an outstanding shine, which is especially effective on polished surfaces like marble and terrazzo. The flexibility of being able to switch between slow/wet and high/dry means contractors can easily adapt the process based on the material and the desired finish. Achieving the Perfect Polish When it comes to the final polish, many stone restoration professionals combine the use of PLP DIPs with polishing compounds such as Majesitc 5X Gold Polishing Powder. After polishing, using a 12,000-grit PLP is highly recommended. This step helps eliminate any residual swirls or heat marks, leaving the surface pristine. It's become a standard part of the finishing process for many in the industry. Wear Indicators for Convenience To make the process even more convenient, the DIPs come with wear indicators in the form of red dots. When the red dot fades, contractors know it's time to replace the pad, as the diamonds have worn out. This simple but effective feature eliminates the guesswork, ensuring that your tools are always in peak condition. The Right Grit for Every StagePLP DIPs are available in a wide range of grit options, starting from 100-grit to 12,000-grit. Lower grit pads used wet and at slower speeds, effectively hone the surface, while higher grit pads, when used dry at higher speeds, deliver that coveted glossy finish. Concrete contractors often use 1500-grit and 3000-grit pads for final burnishing, showing just how versatile these pads are across different hard surfaces. Why Every Contractor Needs DIPsDiamond Impregnated Pads are a must-have for every professional contractor's truck. These pads not only simplify maintenance but also elevate the quality of the finished surface, ensuring client satisfaction. By incorporating DIPs into your maintenance schedule, you can replace traditional brushes and pads, delivering better results in less time. Make the most of your stone restoration projects with PLP Diamond Impregnated Pads. Their adaptability, efficiency, and superior results make them a trusted tool for professionals across the industry.

|