Mastering the Art of Stone Polishing: A Comprehensive Guide to Polishing Granite, Quartz, and More

Comprehensive Guide to Polishing Granite and Similar

Stones

Polishing granite and similar stones like quartz, serpentine

(green marble), and quartzite requires specialized products and techniques to

achieve a high-quality finish. Several products can be used for polishing, each

suited to different types of stone and specific polishing needs.

Overview of Polishing Products for Granite and Similar Stones:

There are several effective products available for polishing

granite and related stones. Among the most notable are Majestic Granite Polishing Powder, Majestic Granite Polishing Compound, and pure tin oxide.

Granite Polishing Powder is available in light and dark varieties and is a

mixture of fine aluminum oxide and tin oxide. This blend is versatile and

effective for different granite types, offering flexibility for various stone

colors and finishes. Selecting the Right Polishing Method for Your Stone Type:

The choice of polishing product and method depends largely

on the specific type of stone and the condition of the surface. It is often

recommended to keep a variety of products on hand to test on a small area

before committing to a full-scale polish.

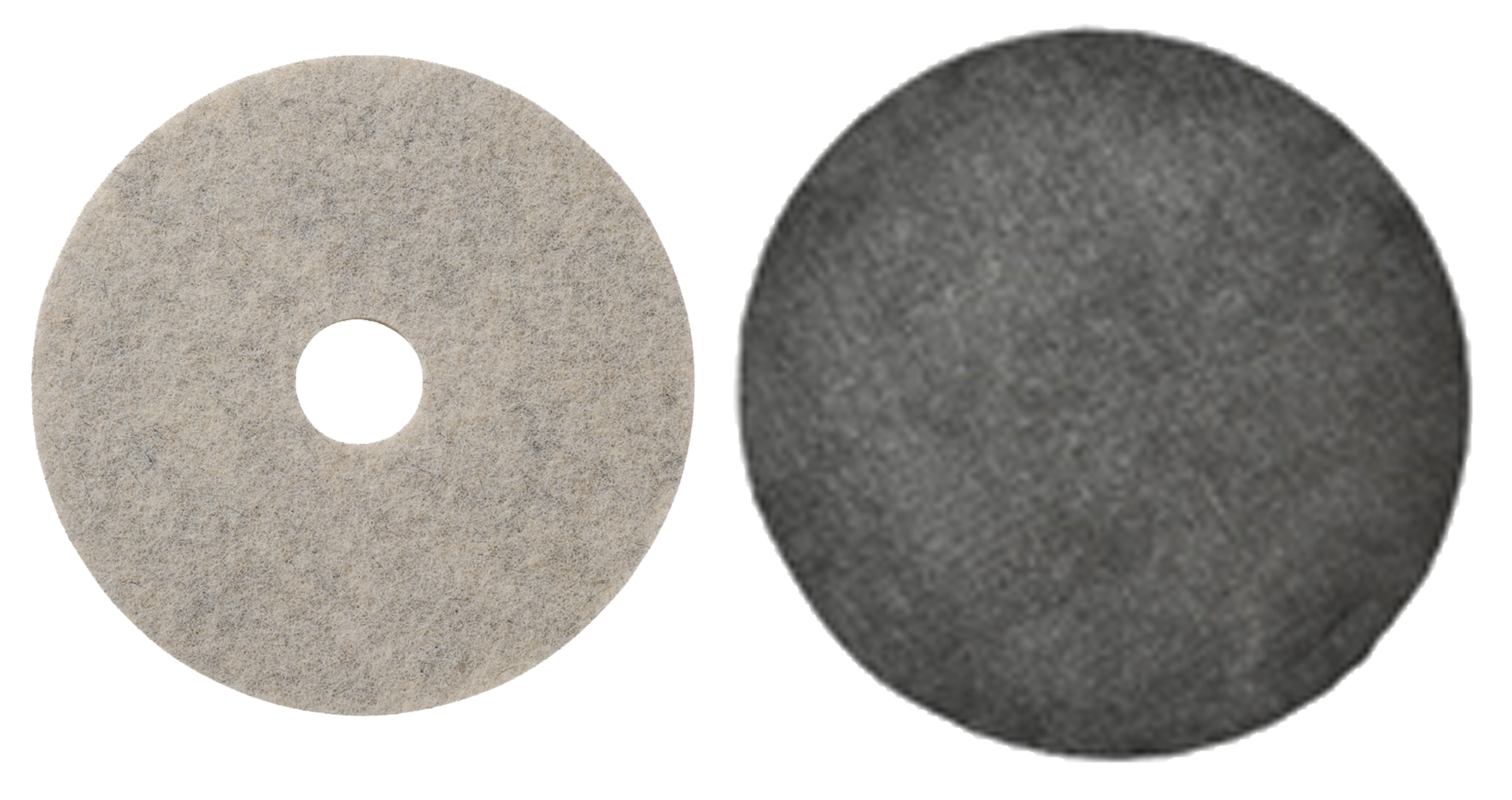

For general maintenance and touch-ups, using a natural or hair pad can be effective. Additionally, the grade #0 steel wool pad has become

a preferred option for many professionals due to its ability to achieve a

consistent polish. When working on countertops or similar surfaces, a hair pad

or #0 steel wool pad, used with a polishing powder or compound, typically

yields good results.

For more intensive polishing, especially after refinishing

or honing the stone, the combination of Majestic Granite Polishing Powder and Majestic Marble Spray Crystallizer is often recommended. This method, however,

requires patience and precision. The process involves applying a small amount

of Granite Polishing Powder to the surface, spritzing with the Crystallizer,

and using a steel wool pad to spread and buff the paste until the desired level

of polish is achieved. Technical Tips for Achieving Optimal Polishing Results:

To enhance the effectiveness of the polishing process, it is

advisable to place a natural pad on the machine's driver, with the steel wool

pad beneath it. This setup helps protect the driver and extends the life of the

steel wool pad by reducing wear and tear.

When polishing, it is crucial to work in small sections,

typically around 9 square feet at a time. This allows for better control and

ensures that each area receives adequate attention. The polishing process

should be repeated as necessary, applying additional Crystallizer to keep the

paste workable until the desired finish is reached. Conclusion: Achieving a Brilliant Finish on Granite and Other Stones:

Polishing granite and similar stones is a task that requires

the right products, methods, and attention to detail. By understanding the

characteristics of the stone and selecting the appropriate polishing products,

professionals can achieve a brilliant and long-lasting finish. Consulting with a distributor or seeking technical assistance is recommended for additional guidance, as it can provide valuable insights tailored to specific needs and

challenges.

|